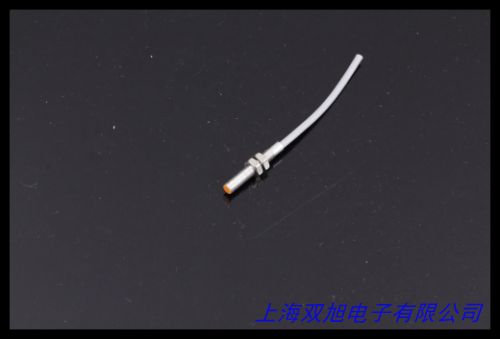

玻璃光導纖維光電傳感器接近開關紅外線光電開關

玻璃光導纖維光電傳感器接近開關紅外線光電開關產品介紹

一、產品概述

玻璃光導纖維光電傳感器接近開關紅外線光電開關是一種先進的光電檢測設備,它利用玻璃光導纖維傳導光線,并結合紅外線技術,實現對物體的非接觸式檢測。該設備廣泛應用于工業自動化生產線、物料輸送監測、安全防護等多個領域,為現代化生產與安全管理提供了高效、可靠的檢測解決方案。

二、產品特點

(一)高精度檢測

該光電開關采用高質量的玻璃光導纖維,能夠精確傳導光線,確保檢測信號的穩定性和準確性。其紅外線檢測技術具有高靈敏度,能夠精準識別微小物體或物體的微小變化,即使在復雜環境下也能保持穩定的檢測性能,檢測精度可達到毫米級別,有效避免誤判,保障生產流程的順暢進行。

(二)非接觸式測量

基于紅外線原理,該設備無需與被檢測物體直接接觸,即可實現距離測量和物體檢測。這種非接觸式測量方式不僅避免了因接觸可能造成的物體損傷或設備磨損,還大大提高了檢測效率和使用壽命。尤其適用于檢測高速運動物體或表面易受損的物體,如玻璃制品、精密電子元件等,能夠在不干擾物體正常運動的情況下完成檢測任務。

(三)適應性強

其工作溫度范圍較廣,能夠在 -20℃至 +50℃的環境下穩定運行,無論是寒冷的冬季還是炎熱的夏季,都能保持良好的工作狀態。同時,該設備對環境光照條件的適應性也很強,無論是強光直射還是昏暗環境,都能通過內部的智能調節機制,保證檢測效果不受影響,使其能夠在各種復雜工業場景中可靠工作。

(四)安裝簡便

該光電開關的結構設計緊湊,體積小巧,便于安裝在各種空間受限的設備或生產線上。其連接方式簡單,只需將玻璃光導纖維與傳感器主體連接,并按照設備的電氣要求進行簡單的線路連接,即可完成安裝調試。此外,設備還配備了直觀的指示燈和可調節的靈敏度設置,方便用戶根據實際檢測需求進行快速配置和調試,大大降低了安裝和維護成本。

三、應用領域

(一)工業自動化生產線

在汽車制造、電子設備生產等工業自動化生產線上,該光電開關可用于檢測零部件的裝配位置、傳送帶上的物料有無以及產品的數量統計等。例如,在汽車發動機裝配線中,它可以準確檢測發動機零部件是否正確安裝到位,確保裝配質量;在電子元件生產線,能夠快速統計通過傳送帶的元件數量,及時發現物料短缺或生產異常情況,提高生產效率和產品質量。

(二)物料輸送監測

對于礦山、港口等物料輸送場所,該設備可用于監測輸送帶上的物料流量、物料堆積情況以及輸送帶的運行狀態。通過安裝在輸送帶兩側或上方的光電開關,實時監測物料的流動情況,當物料流量異常或輸送帶出現故障時,及時發出警報信號,以便采取相應的措施,避免物料堆積或設備損壞,保障物料輸送系統的正常運行。

(三)安全防護

在工廠車間、倉庫等場所的出入口或危險區域,該光電開關可以作為安全防護裝置,檢測人員或物體的進入情況。當有人員或物體進入設定的安全防護區域時,設備會立即發出警報信號,提醒相關人員注意安全,防止意外事故的發生,為生產現場的安全管理提供有力保障。

四、產品優勢

與傳統的機械式接近開關相比,玻璃光導纖維光電傳感器接近開關紅外線光電開關具有明顯的優勢。它不受磁場干擾,能夠在電磁環境復雜的工業場所穩定工作,避免了因電磁干擾導致的誤動作。此外,其使用壽命長,由于采用非接觸式檢測方式,減少了機械磨損,降低了設備的維護頻率和成本。同時,該設備的檢測速度極快,能夠滿足高速工業生產的實時檢測需求,為工業自動化和智能化發展提供了有力支持。

五、產品參數

-

工作電壓:10 - 30V DC

-

檢測距離:0 - 5m(可根據不同型號調整)

-

響應時間:<10ms

-

輸出方式:NPN / PNP 可選

-

工作溫度:-20℃ - +50℃

-

防護等級:IP67

六、產品維護與保養

為了確保設備的長期穩定運行,建議用戶定期對光電開關進行清潔和檢查。清潔時,使用柔軟的干布擦拭玻璃光導纖維和傳感器表面,避免使用腐蝕性溶劑,以免損壞設備。同時,定期檢查設備的連接線路是否牢固,確保電氣連接的可靠性。在使用過程中,如發現設備出現異常情況,應及時聯系專業技術人員進行維修和調試,避免自行拆卸或修理,以免造成設備損壞或安全事故。

玻璃光導纖維光電傳感器接近開關紅外線光電開關以其卓越的性能和廣泛的應用范圍,已成為現代工業生產中不可或缺的檢測設備之一。它為提高生產效率、保障生產安全和提升產品質量發揮了重要作用,是工業自動化領域理想的檢測解決方案。

Introduction to Glass Optical Fiber Photoelectric Sensor Proximity Switch Infrared Photoelectric Switch

I. Product Overview

The Glass Optical Fiber Photoelectric Sensor Proximity Switch Infrared Photoelectric Switch is an advanced photoelectric detection device. It utilizes glass optical fibers to conduct light and combines infrared technology to achieve non - contact detection of objects. This device is widely used in various fields such as industrial automation production lines, material conveying monitoring, and safety protection. It provides an efficient and reliable detection solution for modern production and safety management.

II. Product Features

(i) High - Precision Detection

This photoelectric switch uses high - quality glass optical fibers that can accurately conduct light, ensuring the stability and accuracy of the detection signal. Its infrared detection technology has high sensitivity and can precisely identify small objects or minor changes in objects. Even in complex environments, it can maintain stable detection performance with a detection accuracy that can reach the millimeter level. This effectively avoids misjudgments and ensures the smooth operation of the production process.

(ii) Non - Contact Measurement

Based on the principle of infrared, this device can measure and detect objects without direct contact. This non - contact measurement method not only avoids possible object damage or equipment wear caused by contact but also greatly improves detection efficiency and service life. It is especially suitable for detecting high - speed moving objects or objects with easily damaged surfaces, such as glass products and precision electronic components. It can complete the detection task without interfering with the normal movement of objects.

(iii) Strong Adaptability

Its working temperature range is relatively wide, and it can operate stably between - 20℃ and + 50℃. Whether it is in the cold winter or the hot summer, it can maintain a good working state. At the same time, this device has strong adaptability to environmental lighting conditions. Whether it is in strong direct light or dim environments, it can ensure the detection effect through its internal intelligent adjustment mechanism. This enables it to work reliably in various complex industrial scenarios.

(iv) Easy Installation

The structure of this photoelectric switch is compact and its volume is small, making it easy to install in various space - limited equipment or production lines. Its connection method is simple. You just need to connect the glass optical fiber with the sensor body and connect the wires according to the electrical requirements of the equipment to complete the installation and debugging. In addition, the device is equipped with intuitive indicator lights and adjustable sensitivity settings. Users can quickly configure and debug according to actual detection needs, greatly reducing installation and maintenance costs.

III. Application Fields

(i) Industrial Automation Production Lines

In industrial automation production lines such as automobile manufacturing and electronic equipment production, this photoelectric switch can be used to detect the assembly position of parts, the presence of materials on the conveyor belt, and the quantity of products. For example, in an automobile engine assembly line, it can accurately detect whether the engine parts are correctly installed to ensure assembly quality. In an electronic component production line, it can quickly count the number of components passing through the conveyor belt. It can also detect production anomalies in a timely manner, improving production efficiency and product quality.

(ii) Material Conveying Monitoring

In material conveying sites such as mines and ports, this device can be used as a material conveying monitoring device to monitor the flow rate of materials on the conveyor belt, the accumulation of materials, and the operating status of the conveyor belt. By installing photoelectric switches on the sides or above the conveyor belt, the flow of materials can be monitored in real - time. When the material flow rate is abnormal or the conveyor belt fails, an alarm signal will be issued immediately to take corresponding measures. This prevents material accumulation or equipment damage and ensures the normal operation of the material conveying system.

(iii) Safety Protection

In the entrances and exits or hazardous areas of workshops and warehouses, this photoelectric switch can be used as a safety protection device to detect the entry of personnel or objects. When personnel or objects enter the set safety protection area, the device will immediately issue an alarm signal to remind relevant personnel to pay attention to safety and prevent accidents. It provides strong safety protection for the safety management of production sites.

IV. Product Advantages

Compared with traditional mechanical proximity switches, the Glass Optical Fiber Photoelectric Sensor Proximity Switch Infrared Photoelectric Switch has obvious advantages. It is not affected by magnetic fields and can

玻璃光導纖維光電傳感器接近開關紅外線光電開關

高品質霍爾接近開關 帶LED燈的接近傳感器FHS-U3414C-LED,施克SICK接近開關IME30-10BPSZC0K 誠信明揚工控,日本歐姆龍 OMRON 接近開關 E2E-X5ME1 2M 全新,電感式接近開關 LJ12A3-4-Z/BX 三線常開傳感器 M12,E18-D80NK 紅外避障傳感器 智能小車 機器人 接近開關 3-80cm可調。槽型光電開關SU-07X 三線NPN E3S-GS7N,接近開關 磁感開關,山姆龍接近開關傳感器E2E-X2E1-Z E2E-X5ME1-Z 12-24VDC,亞德客型SE/STMB,SDA氣缸用磁性開關 CS1-G 優質耐用,傳感器 電感式接近開關LJ12A3-4-Z/BX 三線NPN常開。"BAUMER堡盟 10229697 IFRM 06P3713/L 接近開關",高品質接近開關 TURCK/圖爾克開關NI15-M30-RZ3X-H1141,Siemens/西門子3RG4024-3AG33 接近開關 全新 ,Leuze勞易測 IS230MM-2N0-15NO-S12 接近開關。新版蘑菇頭E18-D80NK 紅外避障傳感器 接近開關 直流5V NPN常開,全新接近開關PM08-02N/ PM08-02P, /OMRON接近傳感器E2G-M18KN10-WS-C2 2M, 圖爾克接近開關 NI20-CP40-FZ3X2/S100 圖,RIKO HPD1202-N HPD1202-P接近開關 全新。

上一篇 高品質 意大利BDC磁性三線接近開關BMS8/4609KS傳感器 http://www.uoncy.cn/product/d120622.html

|